How to Operate Hongli Pipe Threading Machine SQ50B1

How to Operate Hongli Pipe Threading Machine SQ50B1

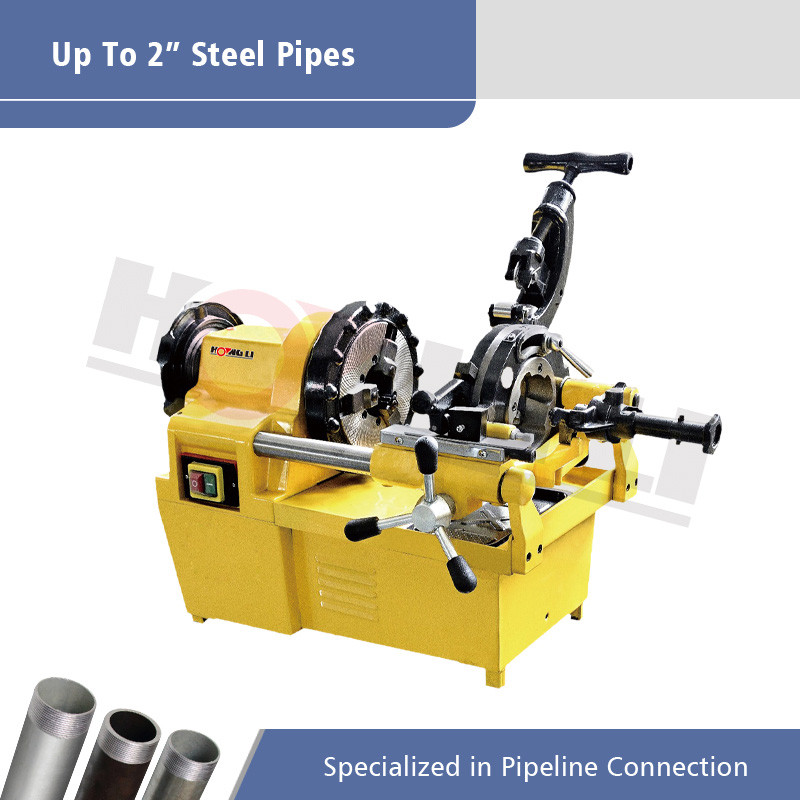

This Tuesday, we members of foreign trade department were learning how to operate Hongli pipe threading machine SQ50B1 type.

Each of us operated once to learn the steps and the issues need to be pay attention to.

Here we have a summary of how to operate the threading machine:

Step 1. Chuck the pipe. We chose one piece of 2" galvanized steel pipe to have tests.

Feed the pipe from the back of the machine body . Then chuck the rear plate and hit the front plate.

Tips: Be make sure the pipe is in the middle of the machine.

Step 2. Press ON button to start the machine, down the cutter to cut the parts not needed of the pipe (for example the part with threads or broken). (if need)

Tips: Turning the handle to right means feeding the carriage and left means return.

Turning the handle of the cutter to right is to cut the pipe and left to release the cutter.

Step 3. Up the cutter and down the die head . Then adjust the sizes of the die head and the corresponding size on the slide key. Both to 2 inch line.

Step 4. Fix the die head to the carriage.

Tips: This step must be after the size adjusting or the size line part will be locked and cannot be adjusted.

Step 5. Start the machine and feed the carriage with die head to the pipe. When the threads forming, leave your hands.

Tips: When the threads be finished, you will hear a noise and the die head will stop threading. That means the threads shaped automatically as per your setting of sizes.

Step 6. Up the die head and down the reamer. Push the reamer blade to the front and chuck to the sink of the reamer handle.

Step 7. Feed the carriage to the pipe to ream the burr for 2 or 3 seconds.

Pipe threading machine

Pipe threading machine Portable Pipe Threader

Portable Pipe Threader Professional Stationary PipeThreading Machine

Professional Stationary PipeThreading Machine Economy Stationary Pipe Threading Machine

Economy Stationary Pipe Threading Machine Threading spare parts

Threading spare parts Pipe grooving machine

Pipe grooving machine pipe cutting machine and tool

pipe cutting machine and tool Pipe cutting machine

Pipe cutting machine Hole cutting and drilling

Hole cutting and drilling Hinged pipe cutter

Hinged pipe cutter Rotary Pipe Cutter

Rotary Pipe Cutter Pipe drain cleaning machine

Pipe drain cleaning machine Pipe installation tools

Pipe installation tools High pressure washing machine

High pressure washing machine Pipe beveling machine

Pipe beveling machine Pipe bending machine

Pipe bending machine Plastic welding machine

Plastic welding machine About HL

About HL Company Certificate

Company Certificate Company Team

Company Team OEM Service

OEM Service FAQ

FAQ Video Center

Video Center