The Developing History of Hongli Hydraulic Pipe Grooving Machines

The Developing History of Hongli Hydraulic Pipe Grooving Machines

Yesterday afternoon, our manager trained us on the developing history of our pipe grooving machines.

Hongli started from a company dedicated in pipe threading machines and spares. Pipe grooving machines were developed as per the requirements of our regular customers.

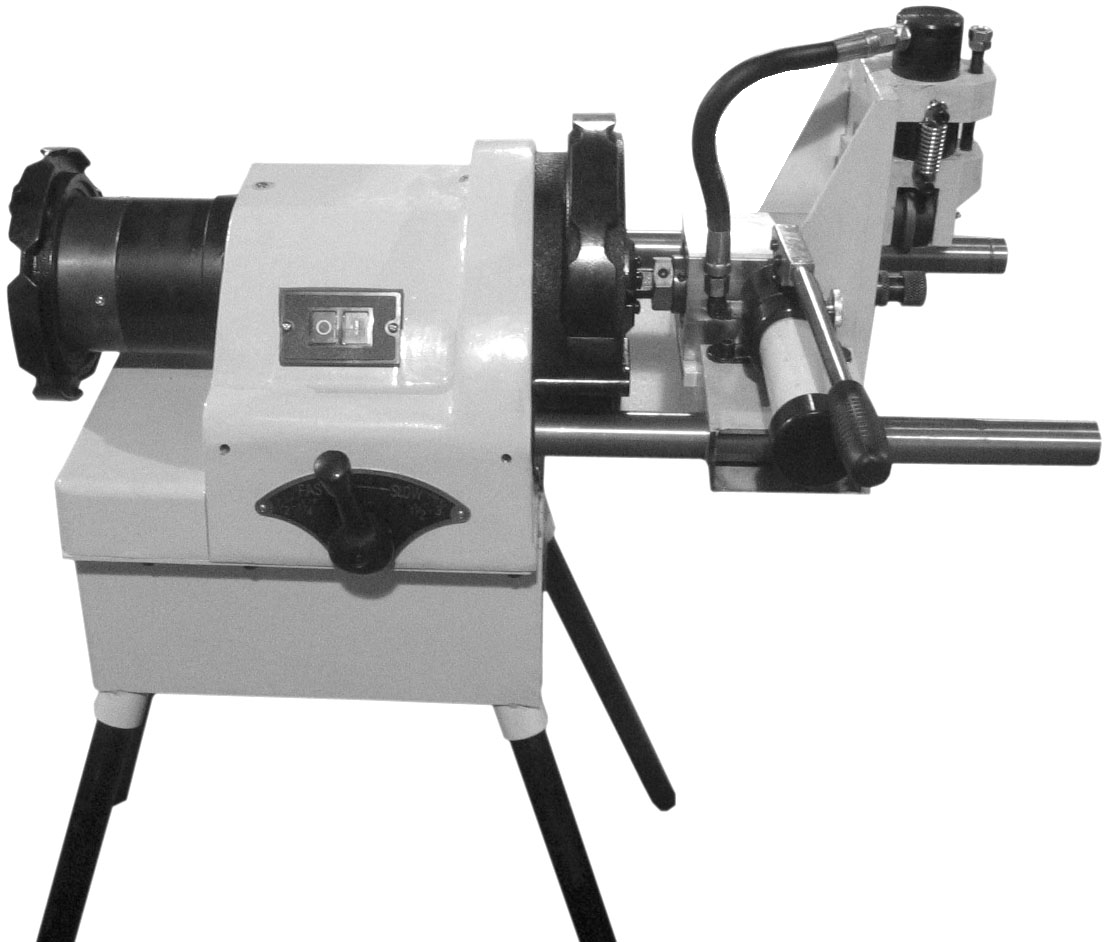

Model GC01 was the first type of pipe grooving machine we developed as per the requirement from one of our regular customers from U.S.A.

The groover is a manual type and it was copied from RIDGID 960. It could be used together with RIDGID 300 power drive and Hongli SQ50D power drive.

Best working capacity is for 1 1/4"-6" pipes.

Below power drive was designed by our own , we called it SQ80C power drive. It was much more heavy duty and suitable for large pipes.

HGC12 was the first pipe grooving machine Hongli researched and developed by our own. No copy.

Still used SQ80C power drive and we added hydraulic system to the groover part.

As we did not make the hydraulic systems by our own, the quality of the hydraulic system was not ensured.

So the machine is not available right now.

YG12A was developed as per the requirement from a customer from Singapore.

YG12A pipe grooving machine was copied from RIDGID 918 pipe grooving machine. Using SQ50D power drive.

The power drive was steady in work and compatible with RIDGID 300 power drive. So the machine is hot sale even right now.

The shafts and the rollers are also compatible with that of RIDGID 918 groover part.

Then, as per the common style roll grooving machine in the market, we developed YG12C pipe grooving machine.

And at the same time, GC02 pipe grooving machine was developed.

Then YG6C and YG6D were developed. They are in the similar appearance style with YG12C. The working capacity is different.

YG12E and YG12D are high-power machines.

Recent years, so many customers need much heavy duty pipe grooving machines for large pipes.

Then we made YG12C be higher power and we manufacture the hydraulic system by our own and update the depth adjusting system. It is to be YG12E pipe grooving machine.

And we are also dealing with a much more heavy duty type YG12D pipe grooving machine in developing right now. The base will be much stronger on the basis of YG12E pipe grooving machine.

Thanks a lot for the customers helped us improve the pipe grooving machines to be better and better.

Any interests please feel free to contact us.

Pipe threading machine

Pipe threading machine Portable Pipe Threader

Portable Pipe Threader Professional Stationary PipeThreading Machine

Professional Stationary PipeThreading Machine Economy Stationary Pipe Threading Machine

Economy Stationary Pipe Threading Machine Threading spare parts

Threading spare parts Pipe grooving machine

Pipe grooving machine pipe cutting machine and tool

pipe cutting machine and tool Pipe cutting machine

Pipe cutting machine Hole cutting and drilling

Hole cutting and drilling Hinged pipe cutter

Hinged pipe cutter Rotary Pipe Cutter

Rotary Pipe Cutter Pipe drain cleaning machine

Pipe drain cleaning machine Pipe installation tools

Pipe installation tools High pressure washing machine

High pressure washing machine Pipe beveling machine

Pipe beveling machine Pipe bending machine

Pipe bending machine Plastic welding machine

Plastic welding machine About HL

About HL Company Certificate

Company Certificate Company Team

Company Team OEM Service

OEM Service FAQ

FAQ Video Center

Video Center