How Do You Check Your Pipe Threading Dies Before You Shipping Them ?

How Do You Check Your Pipe Threading Dies Before You Shipping Them ?

The quality of pipe threading dies are different as per different material, processing technic, heat treatment and surface treatment.

Surface treatment & Packing

Firstly, when we see a set of pipe dies, the surface will be your first impression on it. You will not pay for the threading dies with the appearance of ugly and dirty.

Hongli threading dies can make pipe dies smooth surface, frosted surface, black coating or titanium coating.

Each pieces of threading dies should be applied anti-rust oil. They will be packed by blister cards or small boxes as per your need. The outer package will be plywood case or strong carton as per your shipping way.

Installation & Testing

Actually, the installation and threading testing should be the most important for the orders of pipe dies. That is to say, the threading dies and their die heads should perfect matching.

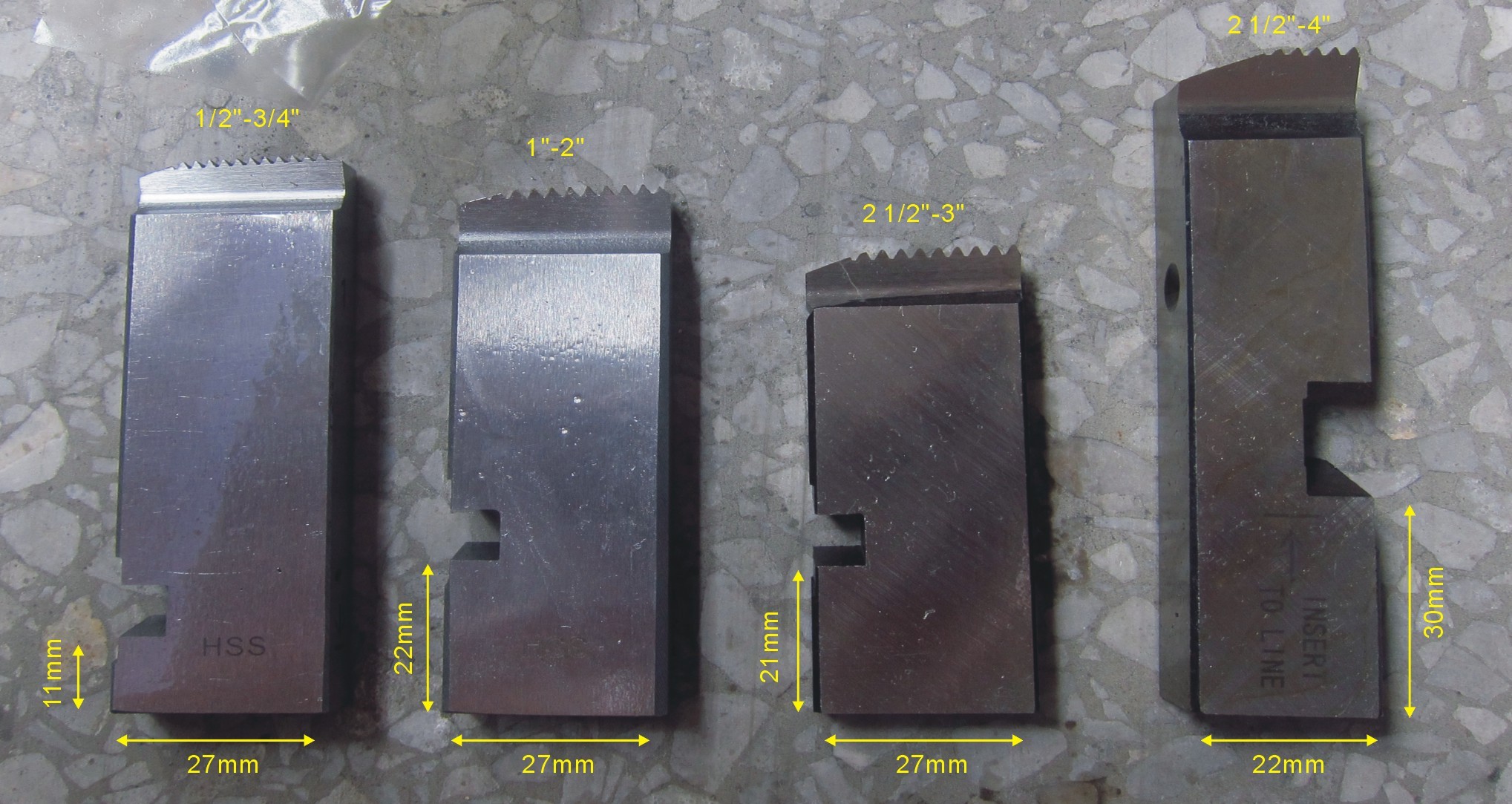

It brings forward a higher requirement for the processing of various external dimensions of the pipe threading dies.

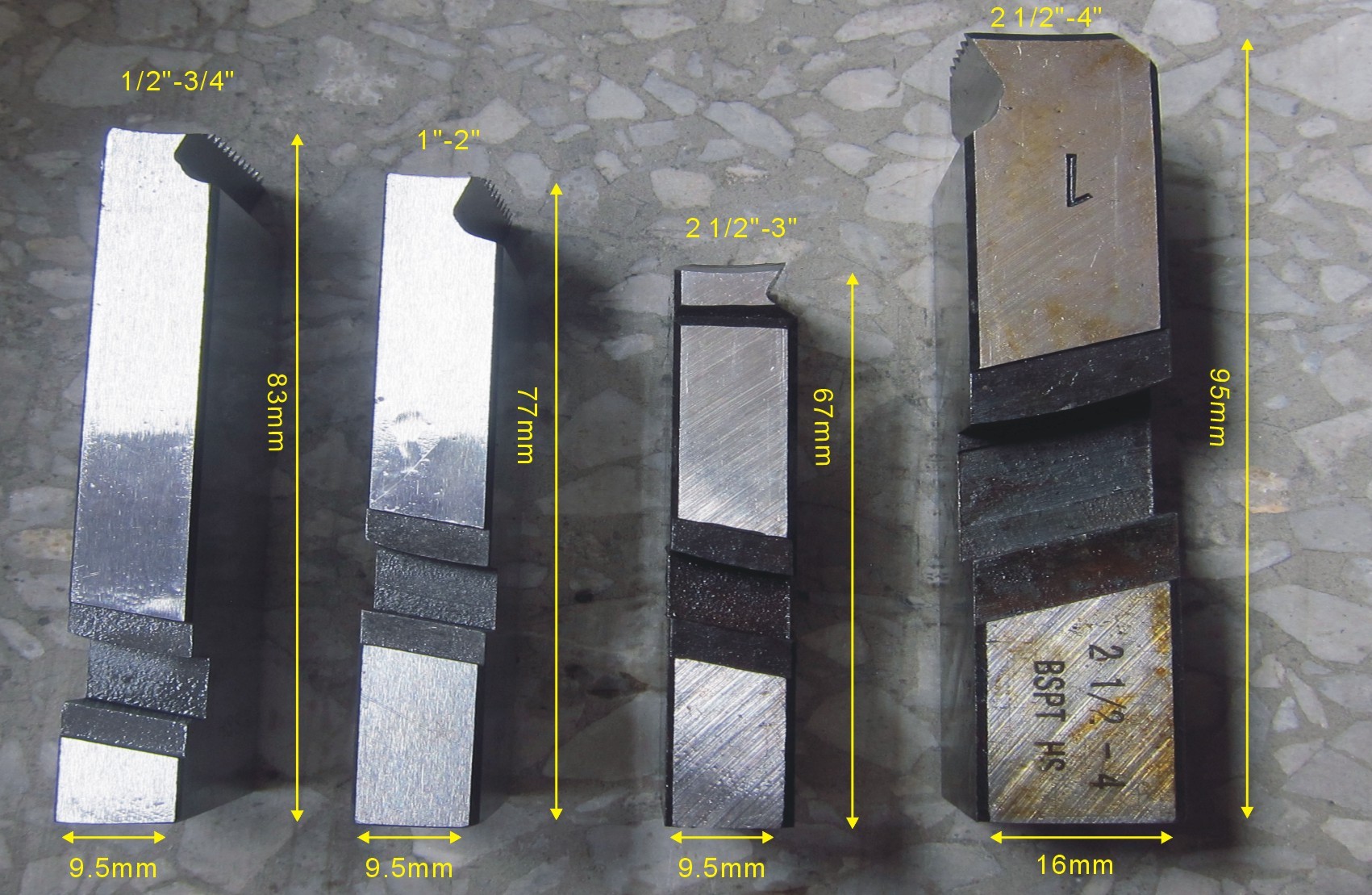

Hongli QC team will check each batch of the dies as per the QC documents. The fast and easy way to check the sizes of threading dies are plug gauge in the picture below:

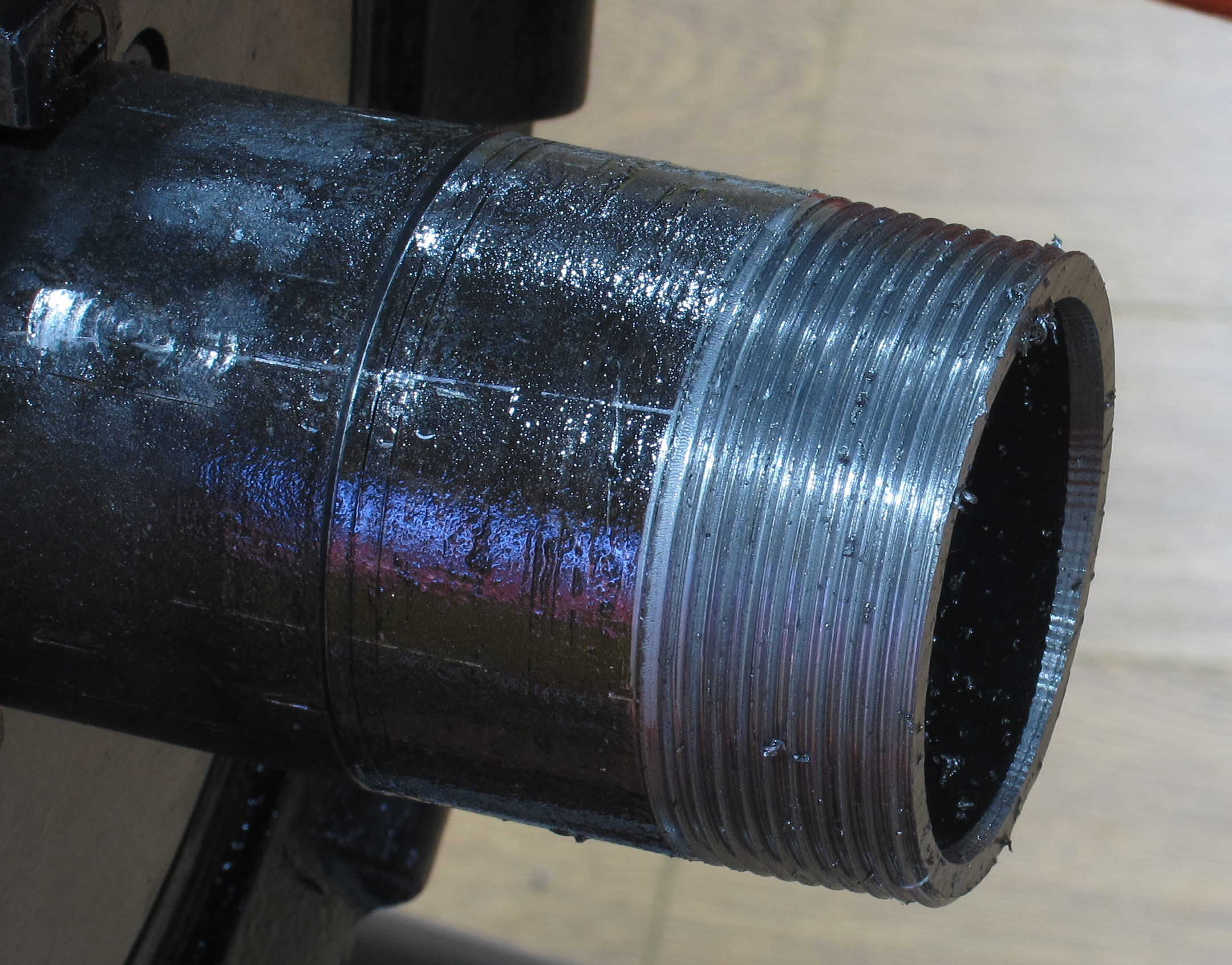

After installation, it will be threading. The effect of the teeth should be reflected from the threaded pipes. We are recording the threading testing conditions of each batch of threading dies.

Below is the pictures of HS dies on galvanized pipes:

Then you can make sure your threading dies are good in use. If there are some problems in installing or testing the pipe dies, you can check your operation at first and then ask our sales representative for help.

Testing site:

Pipe threading machine

Pipe threading machine Portable Pipe Threader

Portable Pipe Threader Professional Stationary PipeThreading Machine

Professional Stationary PipeThreading Machine Economy Stationary Pipe Threading Machine

Economy Stationary Pipe Threading Machine Threading spare parts

Threading spare parts Pipe grooving machine

Pipe grooving machine pipe cutting machine and tool

pipe cutting machine and tool Pipe cutting machine

Pipe cutting machine Hole cutting and drilling

Hole cutting and drilling Hinged pipe cutter

Hinged pipe cutter Rotary Pipe Cutter

Rotary Pipe Cutter Pipe drain cleaning machine

Pipe drain cleaning machine Pipe installation tools

Pipe installation tools High pressure washing machine

High pressure washing machine Pipe beveling machine

Pipe beveling machine Pipe bending machine

Pipe bending machine Plastic welding machine

Plastic welding machine About HL

About HL Company Certificate

Company Certificate Company Team

Company Team OEM Service

OEM Service FAQ

FAQ Video Center

Video Center